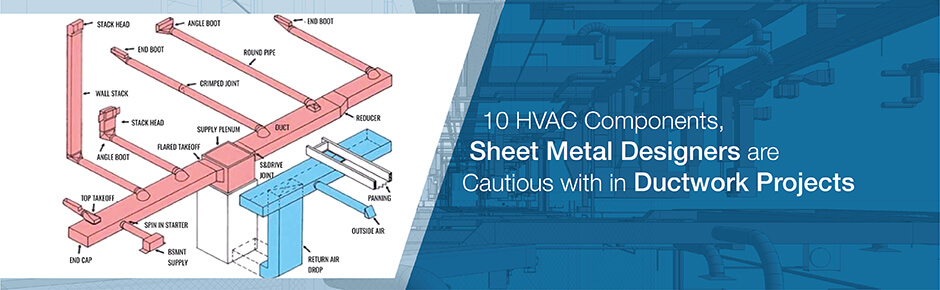

Our Sheet Metal Design Services Offerings:

Our sheet metal design services are tailored to enhance your shop’s capabilities, improve turnaround times, and ensure top-notch quality. We collaborate with sheet metal fabricators and contractors at every stage – from bidding and cost estimation to fabrication and final installation.

2D CAD Sheet Metal Drafting

- Develop 2D sheet metal assembly models and sheet metal parts for flat patterns.

- Produce nesting reports, part drawings, installation guides, and assembly drawings.

- Generate nesting drawings, 2D drawings, and laser cutting for sheet metal with DXF files.

- Incorporate design detailing for boring, punching, bending, drilling, and extruded parts.

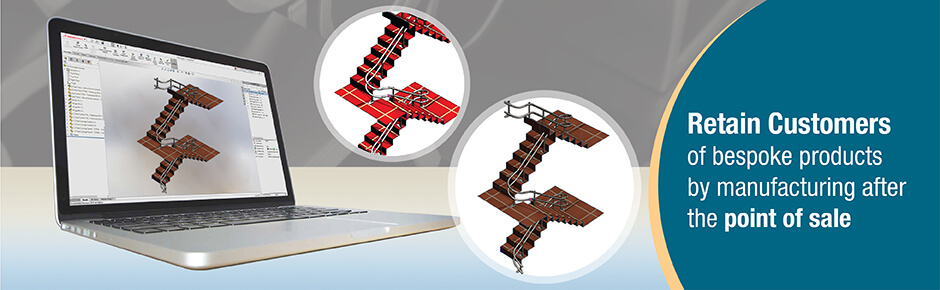

3D CAD Modeling

- Develop 3D sheet metal parts and specify tolerances in metal design.

- Convert solid CAD models to sheet metal components.

- Incorporate bend radius, K-factor, and gauge thickness in 3D CAD models.

- Model base, edge miter, swept flanges, and bends using SolidWorks.

- Generate assembly drawings and installation guides.

- Design weldments, including length, location, and specifications.

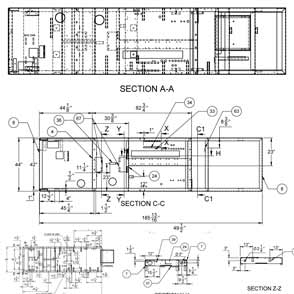

Shop Drawings Submittals

- Simplify complex assemblies by generating VC details.

- Document cutting and shearing needs with dimensions, quantities, and material specifications.

- Specify welding details in design using weld types, sizes, etc. top guide welding processes.

- Prepare a DXF file set for CNC and laser cutting machines.

- Facilitate data exchange by generating neutral file formats like STEP/IGES.

Our Sheet Metal Drafting and Modeling Expertise

We bring extensive experience and a proven track record in CAD drafting and 3D sheet metal modeling for a broad spectrum of sheet metal part products. Our collaborative approach with shop floor engineers ensures that our sheet metal fabrication services are optimized for manufacturing efficiency.

350 +

Sheet Metal Drafting & Modeling for Fabrication Projects

100 +

Tons of Fabricated Sheet Metal Products Designed

85 %

Certified Professionals

100 %

First Time Right (FTR)

Sheet Metal Applications We Specialize In

Grills and Louvers

Doors, Windows, and Frames

Sash, Mouldings, and Trims

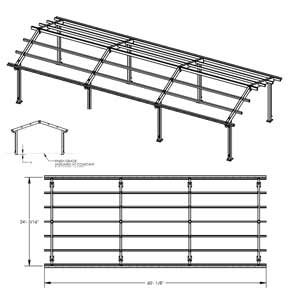

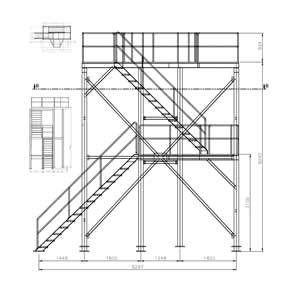

Shelters, Canopies, and Structures

Awnings, Balconies, and Signage

Balustrades and Storage Tanks

Stair Railings and Treads

Steel Stairs and Stair Lifts

Benefits of Outsourcing Sheet Metal Design Services to Us

- Customized solutions aligned with your specific manufacturing processes.

- High-precision drafting for reduced rework and material wastage.

- Comprehensive documentation, including assembly and installation guides.

- Skilled designers and engineers ensure effective and efficient solutions.

- Committed to meet project timelines without compromising quality.

Sheet Metal Design FAQs

Professional sheet metal design services lower production costs through optimized designs for manufacturability. This reduces production time and material use, and mitigated rework and errors using accurate models and drawings.

Industry-standard applications like Autodesk Inventor, SolidWorks, etc. are used to design and model sheet metal components. These tools offer capabilities like K-factor calculations, bend allowance, and unfolding.

3D sheet metal modeling streamlines the manufacturing process as it allows greater visualization, clash detection, and design validation. It supports designers, engineers, and fabricators with error reduction and lower rework.

Comprehensive shop drawings are crucial in sheet metal manufacturing as they provide a blueprint for manufacturers with detailed fabrication specifications like dimensions, materials, and tolerances, which ensure precise manufacturing and risk reduction.

Accurate CAD conversions enhance sheet metal design effectiveness by ensuring data integrity while moving designs between various CAD tools. This ensures a faster production flow and lowers lead times.

Nesting reports support effective sheet metal fabrication and lower material waste by enhancing material use through arrangement of parts on sheet metal to reduce scrap and improve production planning.

For sheet metal drawings, clients are provided with various CAD formats like DWG, DXF, STEP, IGES, and other native CAD file and formats like images and PDFs for review and documentation requirements.