3D product configurators give ETO manufacturers an edge over stand-alone CAD systems to ease product design customization, effectively meeting specific user needs for mass customization.

Table of Contents

With rising mass customization in sheet metal fabrication industry, fabricators find it a herculean task to meet delivery schedules and maintain quality owing to active customer participation. Fabricators are in a dilemma to sustain process agility with design iterations because increased customization adds to design and manufacturing lead times.

By developing product configurators, CAD models can be integrated with manufacturing machines to automate manufacturing tasks and achieve 99% quality. Also, by using interactive product configurator platforms, the buyer has an idea and a 3D view of the product before the placement of final order.

Engineering challenges due to mass customization:

Missed schedules for release of 3D models and manufacturing drawings

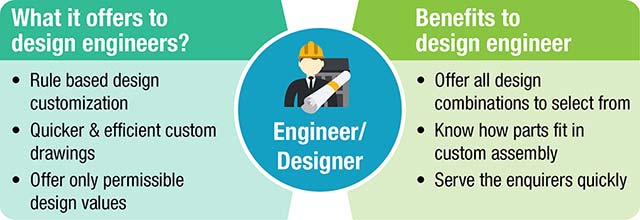

As the design specifications originate from the end-user themselves, developing a generic 3D model that fits all types is not feasible. Each time the design geometry varies, the type, utility, etc. or metallurgy are altered, manufacturing drawings differ. Creating custom drawings for each variant is a time consuming and tedious task and often leads to failure of release of manufacturing drawings on time.

Increased design iterations due to fragmented CAD-CAM

While higher customization adds to the design iterations, weak integration between CAD-CAM systems causes designs to move back and forth from design to manufacturing teams to ensure machinability of the metal.

Unable to meet quality of final deliverables and adherence to time schedules

Repetitive tasks of designing, modeling and raw material availability affect delivery schedules, and keep manufacturers from meeting preplanned timelines. These challenges often end up in design changes and last minute hassles, adversely affecting quality of final deliverables.

As per Gartner, “Application leaders responsible for sales applications should seize the opportunity to disrupt their industry by being the first to offer visual configurations. The first organizations to adopt it in their industry, experience substantial competitive advantage and cost savings.“

So how shall designers and manufacturers address this rising yet bothersome trend of mass customization?For all these roadblocks for manufacturers and designers if there is an established visibility between all the teams – design, manufacturing and sales – majority of the challenges can be resolved.

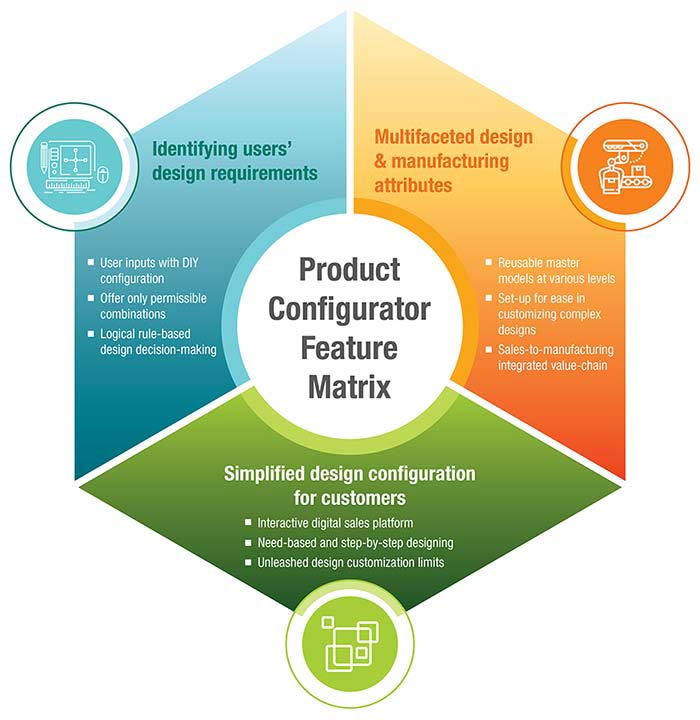

A master model that can be customized at a later stage through a product configuration platform would be an efficient solution. Interactive online product configurators will not only allow the user or the sales team to input geometrical dimensions, but also display a 3D model and quotes for the placed orders, and release manufacturing drawings at the same time.

Interactive configurators, thus, add visibility throughout from sales to design, manufacturing and final order delivery. Further, CAD models can directly be imported to nesting software to eliminate shop floor delays in constantly varying machine tool set up.

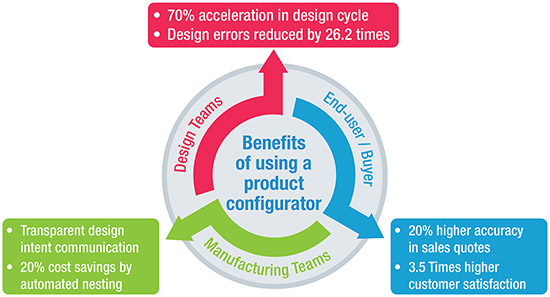

3 substantial benefits of product configurator in custom manufacturing

Manage process workflow and accelerate design cycle times

Design engineers lose 33% of the total design cycle time in customizing and reworking design errors related to manufacturability. Drawings oscillate several times between design and manufacturing departments and it takes several days before their release to manufacturing from the day of sales order receipt.

With product configurator, manufacturers can start actual shop floor work on the day of order receipt. Constraint based logical set of rules in product configurator allows the user to select only the permissible values of design variants and automatically generates custom drawings once the design intelligence is captured in master model. It essentially disregards human intervention in CAD drawing customization and eliminates ECOs from shop floor or design errors. So, configurators work in favor of design engineers to reduce total man-hours and release drawings on time.

Custom door manufacturer reduces cycle time from 5 days to 5 minutes

A US based hollow metal door manufacturer followed a very lengthy process of developing custom drawing in AutoCAD for doors and frames. It took them 4-5 days to respond to their customers with a quote for a simple bespoke door design.

Hitech automation engineers helped the door manufacturer to automate their designs by migrating to SolidWorks models which can be customized at a later stage. Automation experts also developed a rule-based product configurator using DriveWorks Solo and imported SolidWorks models for customization and accelerated the design cycle time.

Impacts:

- Automated repetitive designing task of drawing generation

- Design cycle time was reduced from 4-5 days to 5 minutes

- Released manufacturing drawing for shop floor on the day of order placement

Enabling manufacturers to meet pre-planned delivery schedules

Another major roadblock for custom product manufacturing is the fragmented design handoffs between design and manufacturing teams which pushes back the deadlines. What mass customization demands is an agile and seamless product development workflow to meet both quality and deadlines.

An interactive product configurator that can take inputs from the customer or remote sales team for design specification can streamline the workflow by establishing visibility between teams. Configurators create federated CAD models that can directly be used for sheet metal nesting by integrating CAD data with nesting software.

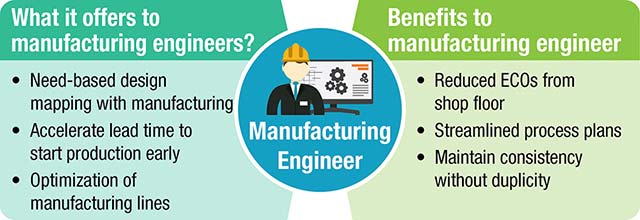

Integration process imports custom CAD models with a predefined coordinate system that facilitates scaling and orientation. Engineers ensure that orientation of each part of the model has a nomenclature similar to that of the nesting tool to automate nesting and generate relevant DXF files. Thus, manufacturing engineer can define rules, surface, forms and finishes for manufacturing operations that incur least possible costs and material scrap.

Manufacturer integrates DriveWorks with SigmaNEST to automate nesting

A US based custom door manufacturer received order requests from end customers through their sales teams which in turn would send the specifications to design team for developing manufacturing drawings. After several iterations the drawings would be released to initiate the actual production. But this process was iterative, and time consuming.

Hitech’s design automation engineers resulted in development of product configurator using SolidWorks and DriveWorks to cut down the design cycle time. DriveWorks models were then assigned coordinate systems and all the CAD data was exported to SQL database and Excel rule sheet for SigmaNEST processing.

Impacts:

- Eliminated fragmented design handoff

- Established process visibility from design to manufacturing

- Integrated nesting software to custom CAD models for quality

Cutting edge response to customer enquiries

Product configurator helps manufacturers in facilitating their potential customers with a guided-selling experience through an online interface. Product configurator, when embedded on a web interface or mobile API, provides an interactive interface to the visitor and let them key in their bespoke specifications. Further, an online interactive configurator also displays a corresponding 3D model with details, gradually, as user makes the selection.

Bespoke Balustrade Manufacturer Shortens Customer Response Time

A UK based global stainless steel balustrade manufacturer and seller grappled in responding to customer enquiries which took about 20 days. Their process was labor intensive which involved extensive cost calculation and manual means of drawing generation for each custom order.

By implementing an online product configurator, the manufacturer shortened the ideal customer response time. It could bring more value to the entire sales process for customer being updated about his orders through immediate emails and benefits to the balustrade manufacturer.

Impacts:

- Generated a 3D view against the selected product specifications

- Immediate and accurate sales quote at the time of purchase

- Enabled access of product related documents with the customer

Conclusion

Mass customization has become vital for manufacturers to stay profitable. Furniture industry, for instance, has already embraced it to a substantial extent. Likewise, building product industry isn’t afar from witnessing mass customization as a mainstream business. By deploying a product configurator you are not only facilitating your customers a better buying experience, but also integrating design and manufacturing teams to make the most of your facilities.

If you are looking for developing product configurator tailored to your customers’ expectations and your manufacturing capabilities, Hitech’s design automation experts can help you achieve your manufacturing productivity goals and sales targets. We help you achieve quality and on time delivery of customized products to expand your client base by establishing trust, Contact us today →

Leave a Reply