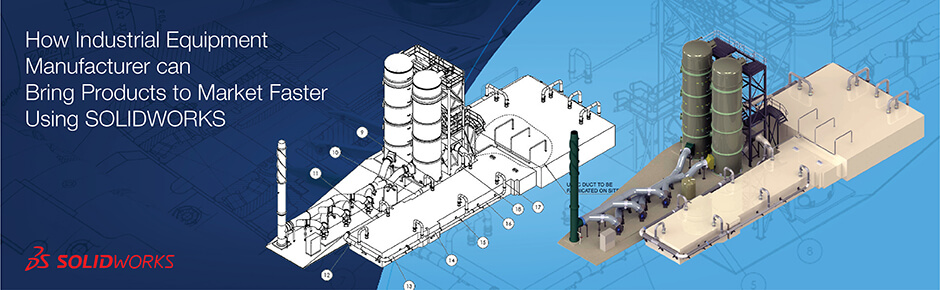

Industrial equipment manufacturers are often strained to meet customer requirements on time, and deliver functioning equipment to the customers. Manufacturers need the right technology tools that can integrate the product development processes seamlessly and enable them to reduce scrap, rework and cost, while maintaining the safety and reliability of the designed equipment.

SOLIDWORKS is one such integrated product development tool that can assist design engineers to connect the silos in the development process and accelerate the time to market the product. Being the most widely utilized design tool across the globe, SOLIDWORKS assists engineers across each and every step of the product development right from concept through fabrication.

Let’s have a look at how this tool serves remains important for integrated product development:

- With SOLIDWORKS PDM, it is easy to bring all team members on the same page to review the design proposal. Engineers, purchasing officers and manufacturing teams can work together and can address the design challenges as well as identify what part of existing assets is required to be leveraged.

- Followed by successfully answering the critical design, purchasing and manufacturing questions, tools in SOLIDWORKS can be utilized to develop a proposal for configurations, risk assessment, cost along with 2D drawings, 3D models and animations.

- Once the proposal is accepted, design engineers can finalize the industrial equipment design by integrating electrical components, evaluating performance and collaborating for manufacturing.

- Shifting the design to manufacturing is also easy with SOLIDWORKS tools which provide the ability to leverage CAD data to develop manufacturing information specific to shop floor requirements. With 3D PMI (Product Manufacturing Information), you can also automate the creation of inspection information.

- The 3D CAD models developed in SOLIDWORKS can be re-used to generate photorealistic renderings to be used in marketing materials, user manuals and maintenance documentation to improve product marketing.

- The tool is also useful for developing CAD models for rapid prototyping. 3D design data can be easily transferred to a printer-friendly format, and the prototype can be generated quickly for design reviews and finalizing the product for mass production.

- SOLIDWORKS also comes with DriveWorks Xpress, which is an intuitive tool to automate the design of custom yet configurable products. Industrial equipment like platforms, storage tanks, etc. can be designed quickly through set of rules for specific applications. Drawings, models, BOMs and cost estimates can then be generated faster and the design can be pushed for manufacturing quickly.

At Hitech, we have been using SOLIDWORKS to deliver engineering design support to our industrial equipment manufacturing clients globally. Through this tool, we have improved efficiency and productivity significantly in developing design and manufacturing information.

Leave a Reply