Table of Contents

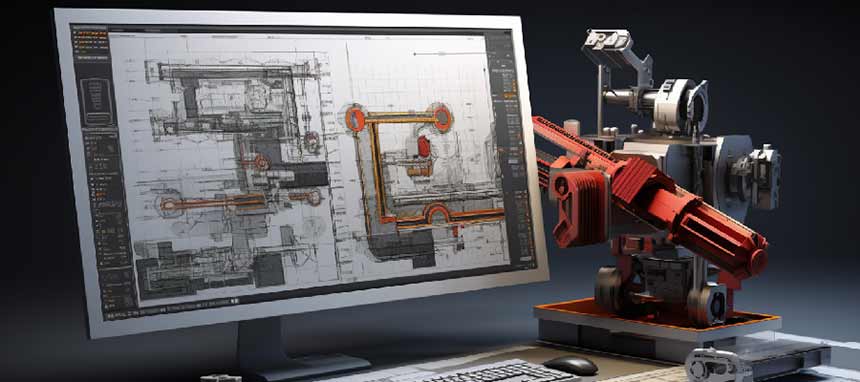

CAD was introduced with an aim to eliminate the painstaking drafting on sheets and eliminate the errors in accurate geometric dimensioning, of crucial industrial parts and machinery components, for manufacturing.

How CAD helps engineers?

Industrial design engineers saw a great relief in communicating their design intent, with help of CAD designing and drafting, to their fabrication contractors or the manufacturing firms. Well-designed, neat 2D CAD draft is much better than a handmade 2D drawing prepared on drawing sheet with rulers and a French curve. Furthermore, a 3D CAD model developed on the basis of CAD drawings, help in communicating every design feature to the manufacturing firm engineers and the foremen operating the machines.

Alternatively, when a manufacturing company is preparing to launch a new product, CAD drafting by design engineer companies remain an integral part during product designing, comparing competitors’ products, and aligning manufacturer’s needs with the design engineers’ goals.

Mechanical product designing in CAD can be done with optimized size, shapes, topology and geometric features of the component alongside its functionality. This helps the manufacturing company reduce the costs of reworks, design engineers to decrease the weight of the product, add strength and cumulatively gain profit in terms of saved time, on the product development cycle.

Significance of CAD during designing

CAD is the software used by mechanical engineers, drafters, and technical professionals in various industries including sheet metal designing, building products, furniture, auto ancillaries, oil and gas, and others.

Being a design engineer, it is very important to know the cost of developing a product by understating the functional requirements and manufacture it according to the shop floor fabricator’s capacity. With the help of CAD design data, saved in form of models in CAD library or SolidWorks/Autodesk vault, design engineers can easily take printouts and start the designing process.

CAD Designing and Drafting, when adopted brings in enlisted advantages:

- Enhancing the designs quality

- Accuracy in geometric dimensioning

- Easy editing of CAD models through parametric CAD

- Strong design communication

- Basis for innovation of different multi-functional designs

- Improve designing process and is economical

- Ensures timely work for the project schedule

- Steps involved in process of mechanical CAD product designing

Ideally, most of the CAD drafting and designing companies follow simple thumb rules and procedure for Mechanical Product Designing. Enlisted is the chronological sequence:

1. Analysis of the product

By analyzing the facts of market and customer needs as well as expectations from the product, different design alternatives and solutions can be easily obtained. It, thus, strengthens the product design and helps iterating new ideas, develop 2D CAD drafts and designs for preparing 3D models and get approvals from concerned product design engineers.

2. Conceptualizing the product’s design

Conceptualization of the design ideas and transforming it into CAD drafts will show correctness of the proposed designs and ensure that they match the industry’s local as well as international standards.

3. Synthesize the product design idea

The ideas that the design engineers conceived during product designing are now created into prototypes and test the design to validate the concepts for functional performance.

It can be concluded that the CAD designing companies develop mechanical products and components based on following:

- Appearance

- Materials

- Dimensions

- Tolerance

- Performance standard

At Hitech Engineering Services, based on your product design needs, we help you adopt CAD systems across your product development stage and manufacturing stage. From CAD Drafting and Conversion to PMI annotated 3D CAD modeling and value engineering through reverse engineering, we remain your extended design arm.

We help you turn your industrial product design ideas into physical products by ensuring low costs, no rework and efficient designing. Drop us an email and our CAD managers will contact you.

Leave a Reply