The right amount of detailing in cabinet shop drawings enhances manufacturing efficiencies by addressing specific concerns of all stakeholders. It promotes collaborative decision-making and enhances quality of the final cabinets.

Cabinets have always been a great favorite with architects to enhance space utilization and add aesthetic value to any constructed space. Cabinet manufacturing involves multiple stakeholders from design, manufacturing and planning, each with their own take on transforming design concepts into tangible products. Unifying diverse approaches for a seamless manufacturing process is a challenge.

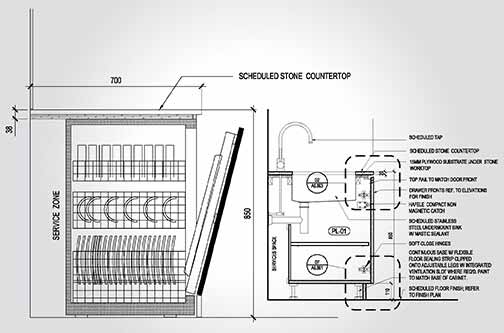

Cabinet shop drawings play a vital role in communicating key manufacturing details such as tolerance values, standard design dimensions etc. across the design-to-manufacturing process. They show the relationship of different cabinet parts with each other and with the building architecture. Detailed CAD drafting facilitates consistent information exchange between stakeholders.

Information challenges in cabinet shop drawing for manufacturers

- Information chaos: Casework shop drawings contain specific information related to fabrication, suppliers, manufacturing operations, instructions for assembly and installation and much more. Information overload often makes reading the drawings difficult and hinders effective decision-making.

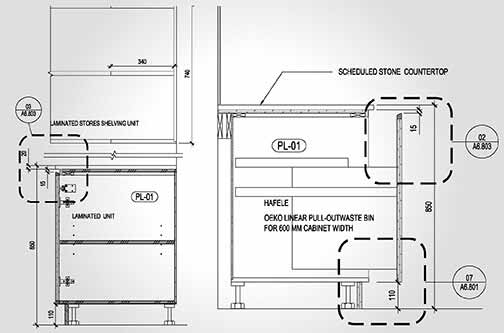

- Dimensional inconsistences: Since cabinet shop drawings contain a myriad of information, designers need to maintain consistency in dimensioning. A slight deviation in measurement leads to reworks and mismatch of products onsite.

Correctly detailed cabinet shop drawings streamline manufacturing operations through seamless design handoff between designer and manufacturer. They deliver enhanced project efficiencies.

Information around cabinet drawings that improve manufacturing efficiencies

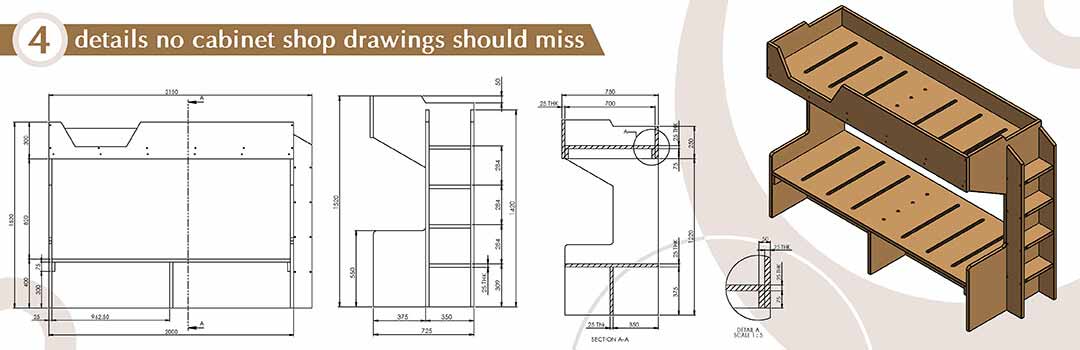

The main purpose of a shop drawing is to bring architects, designers, manufacturers, and contractors on the same page. But each cabinet is unique; so a single drawing will not meet specific needs of all stakeholders. Thus shop drawings need varying amounts of detailing. But there are four essential details that all cabinet shop drawings must have to ensure quality of final products.

1. Stakeholder information detailing for collaborative decision-making

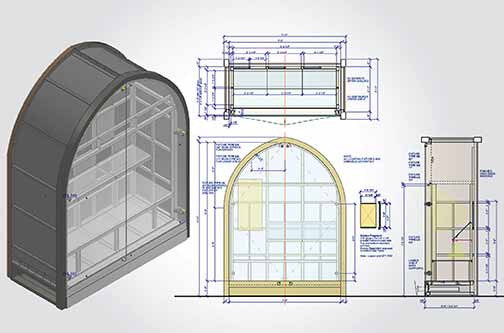

Usually, when a customer orders a cabinet, they specify dimensions and other customizable features such as the number of shelves, doors, type of closure, handles, etc. A CAD drafter incorporates these specifications in the model and when the design is confirmed, detailed shop drawings are prepared.

Cabinet shop drawings contain prescriptive description, manufacturing information, appearance, and performance. They can sometimes be marked up to communicate changes or civil work adjustments. But all in all, shop drawings address the concerns of all stakeholders and empower them with detailed information during decision-making.

When a contractor receives the drawing, he looks for installation related information and instructions. On the other hand an architect would be interested in the design and how it fits with civil construction. For a fabricator, it is always about the material, quantity, manufacturing methods etc. Thus, the purpose of a cabinet drawing is different for each stakeholder.

A detailed shop drawing brings all these stakeholders on same page by communicating all information in one file for a collaborative approach. This kind of design development process leads to faster and robust planning and keeps manufacturing reworks at bay. One can identify and rectify the errors at an early stage.

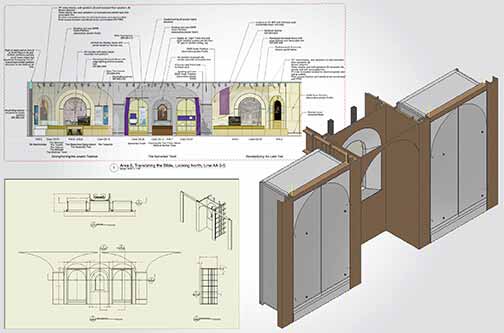

Hitech Engineering Services’ project engineers developed exhibit quality casework shop drawings for a museum in the USA. Team began by developing drawings from architectural floor plans to bring manufacturer and architect closer and enabled the creation of flawless cabinets of glass and wood.

2. Red line markups to adjust for civil work changes

When contractors receive casework shop drawings, they look for assembly and installation guidelines. These drawings are compared with the civil drawings to ensure no conflicts and sufficient clearance for safe installation. If any found, drawings have to be sent back for revisions.

Such issues are predominantly seen in the case of wall-mounted or built-in cabinets. This is because they are designed to fit within the spaces between walls, often called alcoves. To be aesthetic, built-in cabinets require precise design detailing, manufacturing and installation.

With standard geometrical limits and tolerances, these issues are avoided big time. Shop drawings are revised by visiting and inspecting site conditions and civil changes can be accommodated. Using red markup lines, designers can make the early changes before manufacturing begins. Manufacturers can avoid rework and save raw material and time.

3. Detailing for manufacturing and fabrication to minimize change orders

When initial discussions happen between design engineers and woodworkers or metal fabricators, engineers can gauge the shop’s exact tooling capabilities. So while developing construction documents, BOMs, DXF files, and flat patterns, everyone can have realistic expectations.

Detailing particularly helps in custom milling where the tool setting changes frequently. A detailed set of manufacturing documents offers all information at one place and manufacturing can be uninterrupted. Sometimes, these drawings also include cabinet section drawings, cabinet elevation drawings, etc. that provide a visual representation of the boxed components hidden behind the surface.

Hitech Engineering Services’ cabinet drafting teams follow international design standards such as AWI, NKBA, or AWS. This has enabled manufacturers to minimize change orders from the shop floor. Following standards helps eliminate recreation of drawings and manufacturing delays.

4. Assembly and installation guidelines

All cabinets are made of different primary materials and some are more delicate than others. Foremen on site are neither equipped to understand the delicacy of each component nor do they know of the criticality of connectors. Additionally, modern cabinet makers deliver DIY assembly.

It thus becomes important for the manufacturer to provide installation guides and assembly instruction manuals. A cabinet assembly drawing with instructions, footnotes, drawings, symbols, annotations, etc. helps understand the functioning of each component. These guides are sometimes accompanied by the material, list of fasteners, adhesives, and more to install the product properly.

The way ahead

Advanced software development brings intelligible sensing, intuitive designing, practices to adhere to international drawing standards, and recommendations for shop drawing optimization. They also have provisions that hide/unhide features based on who is accessing the drawing to avoid information clutter. These qualities enhance designers’ productivity and uplift inter-team coordination.

Detailed shop drawings not only help you highlight and remove inconsistencies but also ensure that those mistakes are not dragged to the next stage of manufacturing. You get to save a lot of time, rework and cost. But more importantly, with a detailed cabinet shop drawing, the entire manufacturing process is streamlined and the final product has a better finish and form.

error-free cabinet shop drawings

Leave a Reply