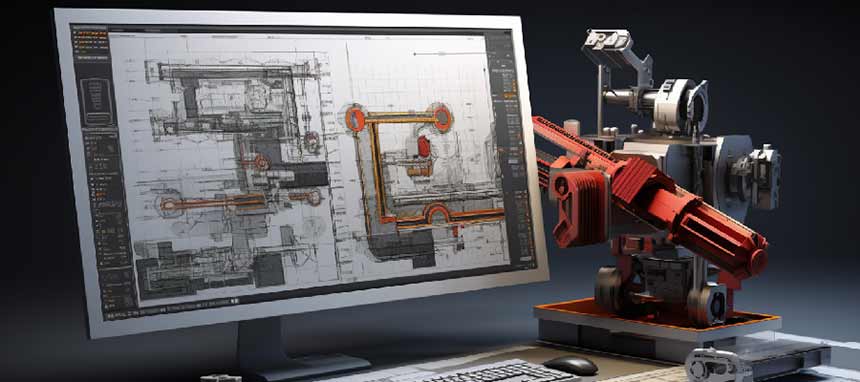

As Millwork furniture evolves in terms of design and manufacturing needs, CAD drafting and drawings give it much needed power to forge seamless and error free manufacturing processes.

Integrating latest design trends with ease, accuracy, and cohesive manner into the millwork manufacturing process, calls for meticulously executed drawings and proper information flow between furniture designers and manufacturers.

CAD drawings offer an effective communication channel to eliminate design information glitches and enable uninterrupted manufacturing. Details warehoused in millwork shop drawings depict functional needs of every sub-assembly and components for enhanced manufacturing and post-manufacturing stages.

6 benefits of CAD drafting for millwork furniture manufacturers

1. Ultimate control over manufacturing

Millwork CAD drawings ensure manufacturing accuracy by including comprehensive technical details about the furniture products being manufactured and their internal part alignment.

- Detailed information sharing: Millwork shop drawings present product details from different views such as top, front and sectional. Multidimensional views help shop floor managers understand how each part of the entire furniture assembly fits in with the other. They also help execute the manufacturing process with almost zero deviation.

- Getting approvals for design changes early: Digitized CAD drafts for millwork manufacturing allow designers to explore modifications as per customer’s input. Designs can be tweaked and experimented to receive approval before investing in manufacturing and save costs.

2. Facilitates prefabrication

Detailed millwork CAD drawings enable offsite manufacturing of components and their seamless assembly and assimilation into current setup.

- Along with the minutest component details, CAD drawings also include information on how the furniture piece would fit into the walls.

- Millwork shop drawings and their installation guides include information right from unboxing the packaging on site to fixing bolts and nails to avoid any errors. These details help manufacturers guide assemblers and customers in fixing the furniture without hassles.

3. Convenient File Formats

Millwork manufacturing involves extensive data exchange between several stakeholders. Often the design intelligence is lost during this exchange across different platforms. However, the multiple file formats of CAD offer seamless communication between teams and across platforms.

For example:

- Neutral fire formats such as IGES or STEP are typically used for cross platform exchange.

- DWG, DWF or DXF are widely used for final design output for design communication with manufacturers.

- Scan to CAD is another way to convert any file format such as TISS, PDF or vector images into DWG format to create editable CAD drawings.

Furthermore, DID Sections in CAD drawings can project either a vertical slice or a cut-through view of your customized wooden or metal furniture parts. For instance, in a customized millwork cabinet, these additional views are critical in fixing cabinets as they provide additional information about the component.

Error-free Millwork CAD drawings ease museum furniture manufacturing

A US-based institutional furniture design and manufacturing firm working on preparing architectural designs for a historical museum partnered with Hitech Engineering Services. They required precision millwork shop CAD drawings to communicate the right design intent on the shop floor. Once the multiple furniture components were modeled, the firm also wanted quick manufacturing solutions with easily available drawing format.

Hitech engineers delivered:

- Error-free shop drawings in AutoCAD created in PDF format.

- Uninterrupted fabrication opportunity with documents like design process monitor, project register, material information, equipment call off and design change register.

4. Space optimization while manufacturing

Millwork shop drawings are developed from native architectural plans which allow you to consider available space and floor area giving you better control over designs. Every inch can be used efficiently and you can eliminate cramped or irregular looks within the space.

This helps you offer sophisticated and high dimensional customized products to your customers.

Retail food chain deploys CAD configurator to reduce lead time and cut costs

A retail food chain from the US faced issues in customizing designs as per space availability. Iterative design processes to customize the designs led to high errors and material waste due to scrapping. Our DriveWorks specialists collaborated with the manufacturer to convert all drawings into CAD format and deploy a CAD configurator to speed up the time and make customization error-free.

This partnership resulted in:

- Reduction in lead time from 5 to 6 days to one day

- Better space utilization as per custom architecture

- 70 times faster design cycle

- Reduced material scrap during machining

5. Precise display of functionality

Millwork CAD drawings offer a clearer view of the design intent, essence of each design feature and the material. They clearly communicate the durability of finished products to the shop floor.

CAD Drawings can demonstrate all functional capabilities of furniture/metal customized models. For instance, if it’s a metal locker, the CAD Drawings show how each part of the locker functions, if it’s a wooden cupboard, how the doors are opened and up to what specific angle can be envisioned. So, detailed CAD drawings help manufacturers understand the mechanisms of the customized 3D models, making the sales process simpler.

6. Better design understanding for easy installation

To ensure that your millwork drawings are communicated error-free, it is important to follow Geometric Dimensioning & Tolerance[GT&T]. CAD drawings do it without deviations and as per industry standards.

For instance, to manufacture a wooden wardrobe with x number of different parts, dimensioning and their numbers and fixture need to be clearly and accurately communicated. For current design tools, the GD&T methodology has been upgraded providing all the necessary information correlated with a wood/metal component including:

- Limits and fits

- Material name

- BoMs with Manufacturing & assembly part number, revision number, material etc.

With the help of in-depth details in the CAD drawing, your shop floor members not only find the manufacturing process simpler but can also assemble each part more precisely.

Wrap Up

CAD Drafting is an effective and simple way to reduce your manufacturing issues for complex millwork and furniture designs. To be more precise, millwork CAD drawings help deliver customized wooden or metal furniture pieces on stipulated time.

Today’s fast-paced and customer dominated market is seeing an exponential rise in the demand for customization in furniture designs. Ensuring quality and on-time delivery is a challenge in such a situation. But CAD can ensure benefits in various aspects from design to manufacturing and help easily tackle the quality and deadline challenges.

Leave a Reply